Why we use polyester for our flysheets?

Generally, modern tent manufacturers, have a choice of two fabric types for flysheets: nylon or polyester. Both of them have their advantages and shortcomings. Taking them into account - we have decided to use polyester. Why?

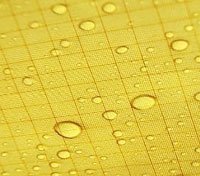

1.This material has almost zero water absorption, which is why after the rain polyester flysheets do not “sag” as those made of nylon. This make the outer shell of the tent always properly tense and there is no contact between wet flysheet and not come into contact with the inner canopy.

2. Polyester has higher UV resistance, which makes the operational lifetime of the flysheets longer.

3. The polyester fabric that we use has three layers of waterproof PU coating. This ensures full integration of the sealing tape with the flysheet, making the seams of our tents fully leak-proof for many years.

The main disadvantage of polyester fabric when compared to nylon are weaker fibres. Therefore, in order to maintain similar strength properties, polyester fabrics have a higher basis weight than those made of nylon, by approx. 30%. This make polyester tents slightly heavier than nylon tents.

Konstrukcja uzyskuje w ten sposób najwyższą odporność na silne wiatry i pozwala na wyjątkową

łatwość i szybkość rozbijania namiotu.

* wyjątek: Axum When camping on snow, you don’t have to leave your tent to get snow for water *. A special flanged floor hatch, secured by a string, may be used after making a cut in indicated area.

* K2 Expedition, Komodo Plus

Materials

For our tents we select the best available materials to ensure peaceful rest of their users, even in the toughest weather conditions. In our production we use fabrics that are maximally resistant to sun, water and mechanical damage, but at the same time as lightweight as possible.

What is important – all Marabut tents are produced in the same manner applying the best production techniques available. There is no compromise when it comes to quality! Customers are assured that, regardless of the chosen tent type (for recreational camping, high mountain expeditions), the quality of materials, technology and workmanship are not compromised

Flysheet

For producing the flysheet of our tents we use 100% Polyester, Rip-Stop, UV, PU 3000mm

Below we explain these terms used are provided below:

Polyester (PES) is a type of synthetic material

Rip-Stop - a term used to indicate that a fabric with this marking has improved resistance to tearing. This feature is achieved by adding reinforcement threads that are interwoven at regular intervals. Rip-Stop fabrics are easily recognized due to a crosshatch pattern.

UV marking indicates that the fabric contains a stabilizer, which minimizes damaging impact of UV rays

PU, means that the fabric is impregnated with polyurethane, which makes it waterproof, at the level of 3000 mm of water column

Many tent users mistakenly assess the quality of the tent basing only on its water resistance, but we suggest taking into account the following facts:

1. Different fabric manufacturers apply different methods of measuring waterproofness, (according to some measurements our tropics flysheets have higher waterproofness than we declare)

2. The watertight integrity of the flysheet depends not only on the quality of the fabric it is made of, also on properly taped seams. Therefore, we suggest customers to always check the quality of taping. For taping tent seams Marabut uses the latest technology based on thermo-adhesive tape applied on the seams.

Why we use polyester for our flysheets?

Generally, modern tent manufacturers, have a choice of two fabric types for flysheets: nylon or polyester. Both of them have their advantages and shortcomings. Taking them into account - we have decided to use polyester. Why?

1. This material has almost zero water absorption, which is why after the rain polyester flysheets do not “sag” as those made of nylon. This make the outer shell of the tent always properly tense and there is no contact between wet flysheet and not come into contact with the inner canopy.

2. Polyester has higher UV resistance, which makes the operational lifetime of the flysheets longer.

3. The polyester fabric that we use has three layers of waterproof PU coating. This ensures full integration of the sealing tape with the flysheet, making the seams of our tents fully leak-proof for many years.

The main disadvantage of polyester fabric when compared to nylon are weaker fibres. Therefore, in order to maintain similar strength properties, polyester fabrics have a higher basis weight than those made of nylon, by approx. 30%. This make polyester tents slightly heavier than nylon tents.

Taking all the above features into account, we have decided that polyester would be the best choice when it comes to the balance between the weight and operational lifetime of our tents. We want the customers to enjoy our tents for long years, not only a few seasons.

Floor

The floor in our tents is made of a three-layer fabric, which is highly waterproof and resistant to mechanical damage.It is laminated on both sides with LDPE and woven on a warp made of HDPE. This fabric is highly waterproof and very strong (important feature when camping on rocky ground, typical for mountains). Basis weight: 110g/m2

Why we use polyethylene floor?

In the pursuit of lightweight solutions, many manufacturers use light, nylon floors. They are indeed very light, but unfortunately not so perfect when it comes to water resistance and mechanical strength, often requiring additional protection. Costumers, checking tent parameters, tend to forget about strong floor. Therefore their backpacks will be additionally burdened by an extra floor protection (approximately 0.3 - 0.5 kg). We suggest remembering about this important feature instead of paying attention only to the catalogue weight of a tent.

Flysheet integrated with the inner tent

This is an important solution, which is worth mentioning. In many tents the flysheet is put over the inner canopy and both of them are connected by cords or Velcro tape. In really bad weather conditions, this connection is hard to make and during heavy rains almost impossible.

Marabut tents have their flysheet integrated with the inner tent, but this connection is detachable. Tent poles are inserted into pole sleeves making the setup process quick and easy. The inner canopy is always dry even when the tent is set up in the rain. This solution significantly shortens and facilitates the set-up process. Once you try it and feel the difference – you will not want to use any other solution. *

Why we use nylon for inner tent?

Nylon fabrics are very flexible preventing mechanical damage of canopy and fixing points in normal use and in extreme conditions. Common polyester fabrics used for manufacturing inner canopies do not have this advantage.

* excluding: Axum – separate flysheet

Tent poles

Marabut tents are equipped with two types of tent poles, depending on the model:

1. Aluminium poles: alu 7001 T6, diameter: 9,5 mm

2. Glass fibre poles (various diameters)

Aluminium poles are lightweight and more resistant to mechanical damage than other poles. The weight of a tent equipped with aluminium poles is lower by 20-30% comparing to other solutions. Therefore we use aluminium poles in tents designed for hard and extreme conditions, whereas tents for recreational camping have poles made of glass fibre.

External tent poles

Almost all our tents have a system of externally mounted poles*.

This type of tent structure ensures the highest resistance to strong winds and makes the set-up operation exceptionally quick and easy.

* excluding: Axum

All seams taped

All seams in our tents are taped with a thermo-adhesive tape ensuring full waterproofness.

Light-reflecting inserts

Corners of our tents have light-reflecting inserts. These details help campers to set up tents in the night-time or during bad weather and help to find tents when the visibility is reduced.

Molding system

This system ensures correct positioning of the flysheet over the inner canopy. We use buckles produced by National Molding, a world leader in producing plastic buckles and fasteners.

Snow flaps

In order to ensure the maximum safety during snow camping, all our expedition tents are equipped with snow flaps. They may be easily detached and rolled, when not required.

Side pockets

Net pockets attached along the side walls provide a neat and organised storage space for all small items that must be at hand.

Suspended shelf

A net shelf suspended under the ceiling is a perfect place for items that must be easily accessible, e.g. torch, glasses etc.

Threads

We use strong COATS threads.

Zippers

Zippers in tents must be durable, unbreakable and resistant to material stresses. To achieve these features, we have chosen the best available zippers produced by YKK, Coats and Alpha.